The cement production line we design is a new dry process cement production line based on the traditional cement production process and improved by the current market requirements and user requirements. Compared with the traditional production process, it has strong adaptability to sticky and wet materials, stable production system, and the clinker quality can fully meet the high market requirements. In addition, the production capacity of the production line has also been improved For cement production enterprises, it is an ideal production line worthy of investment.

The whole process of cement production line generally includes:

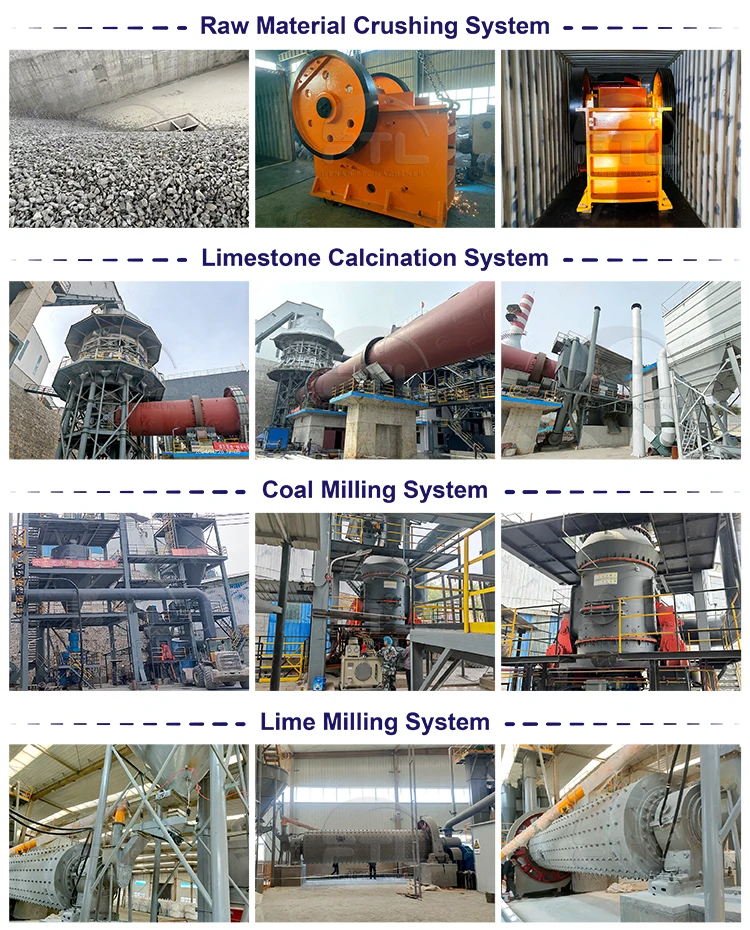

Step1: crushing and pre homogenizing, crushing limestone and other raw materials,

Step 2: raw material preparation;

Step 3: raw meal homogenization. The raw meal homogenization system plays a key role in stabilizing the composition of enter pit raw material.

Step 4: preheating and decomposition, which completes the preheating and partial decomposition of raw material by preheater, replacing some functions of rotary kiln.

Step 5: Which is the core step, The rotary kiln is used to produce cement clinker, and then the cement is grinded to form a certain particle size distribution.

In this way, the whole production line process is completed. The production line is safe and environmental protection, with large production capacity and obvious investment advantages.

Previous: NONE!

Next: Cement Rotary Kiln