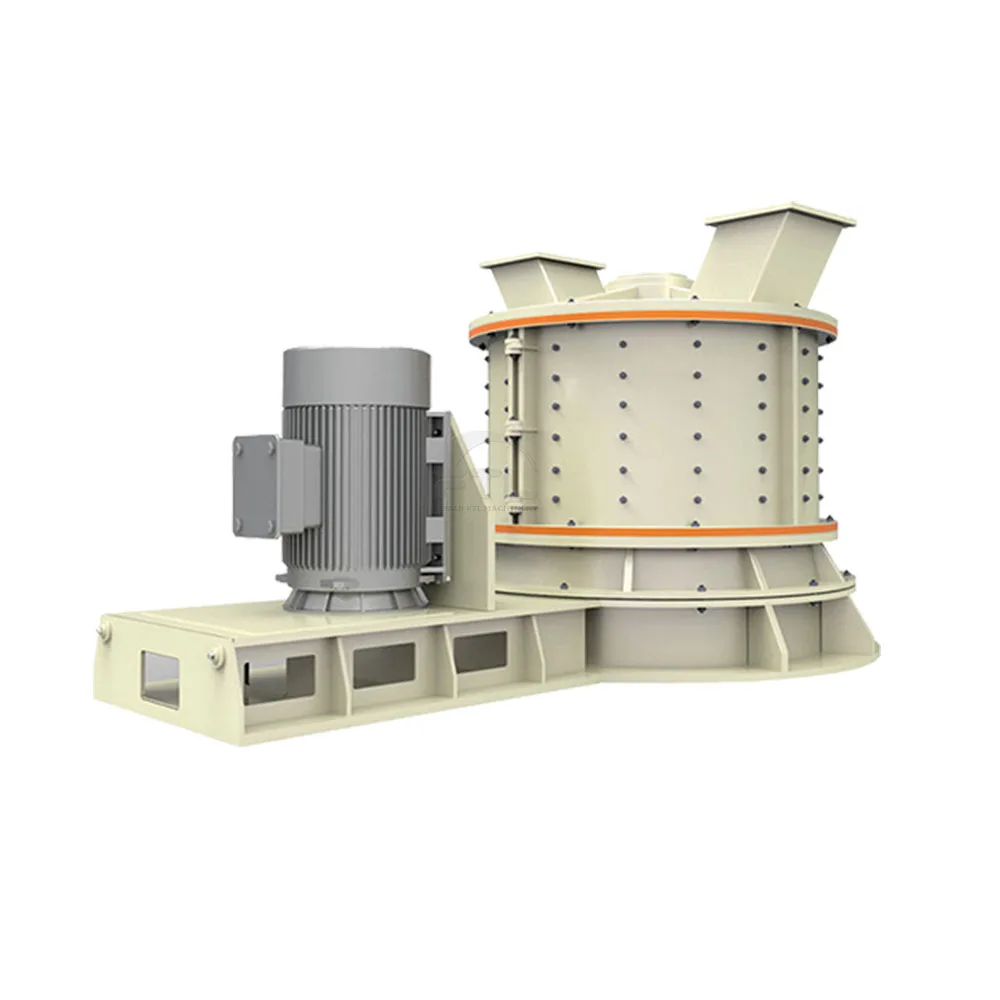

Complex Crusher

Vertical complex Crusher is suitable for material crushing operation with the compressive strength not more than 160MPa , with big crushing ratio, less energy consumption, stable operation, simple structure, easy operation and maintenance and so on.It is an ideal fine crushing equipment

Vertical complex Crusher is suitable for material crushing operation with the compressive strength not more than 160MPa , with big crushing ratio, less energy consumption, stable operation, simple structure, easy operation and maintenance and so on.It is an ideal fine crushing equipment.

PFL vertical complex crusher is primarily used for breaking stones.

Introduction:

Composite crusher is a kind of no screen adjustable fine crushing machine,it is optimal designed on the basis of advanced fine crushing technology both at home and abroad. It is mainly adapted to medium-sized raw materials and clinkers , at the same time can also be used for fine-crush dolomite, coke precious stones, lead-zinc, serpentine, blast furnace slag, coal gangue , phosphate rock materials with medium hardness , especially suitable for hard limestone, dolomite, granite, basalt artificially build sand or highway pavement stone processing.

This crusher has big breaking ratio,discharging size is adjustable

8.little wearing of the impeller , easy maintenance.

, don't suffer from the wear of plate hammer and the plate,it is not easy to plug when crushered high moisturelarge mud containing materials; Using elastic and regulatory stucture, the material which can not brken ,they will be automatically discharged,it cant make the damage to equipment;the bearing is horizontal and with long life, it can break high temperature materials (such as cement clinker); unique rotor structure,when break materials, the rotor body is virtually non-wear; the behind Cavitiy set-up screwrod or hydraulic open structure,do not need main equipment you can easily replace the easywearing parts.

Model | Max. Feed Size(mm) | Material-out Size(mm) | Capacity(t/h) | Main Shaft Speed (r/min) | Power(KW) | Overall Dimension(mm) |

PFL-800 | 100 | <3-5,60-90% | 10-20 | 934 | 30-45 | 2100×1200×1700 |

PFL-1000 | 120 | <3-5,60-90% | 20-40 | 769 | 55 | 2600×1400×1900 |

PFL-1250 | 150 | <3-5,60-90% | 40-70 | 530 | 90 | 2800×1600×2100 |

PFL-1500 | 180 | <3-5,60-90% | 70-100 | 495 | 132 | 3100×1900×2200 |

PFL-1750 | 200 | <3-5,60-90% | 100-130 | 424 | 160 | 3710×2360×2390 |

PFL-2000 | 220 | <3-5,60-90% | 100-160 | 370 | 185 | 4100×2660×2620 |

Working principle:

Materials fall into the high-speed rotation impeller from the above of machine, under the action of high-speed centrifugal force,have high-speed impact with another umbrella form materials which flow around the impeller, after they attack each other, then discharged from the bottom,it forms close-circuit and with many times circulation,it can achieve the required product size by screening equipment controlling.

Features:

1.simple structure low operation cost. Using the principle of stone strike stone , smaller wear.

2.broken rate is high, energy conservation

3.with fine, coarse grinding function

4.little affected by material moisture content, humidity can reach 8%.

5.working noise is less than 75 db, less dust pollution.

6.suitable for breaking medium hard, especially hard materials.

7.products are cubic, packing density is big, a very small iron pollution