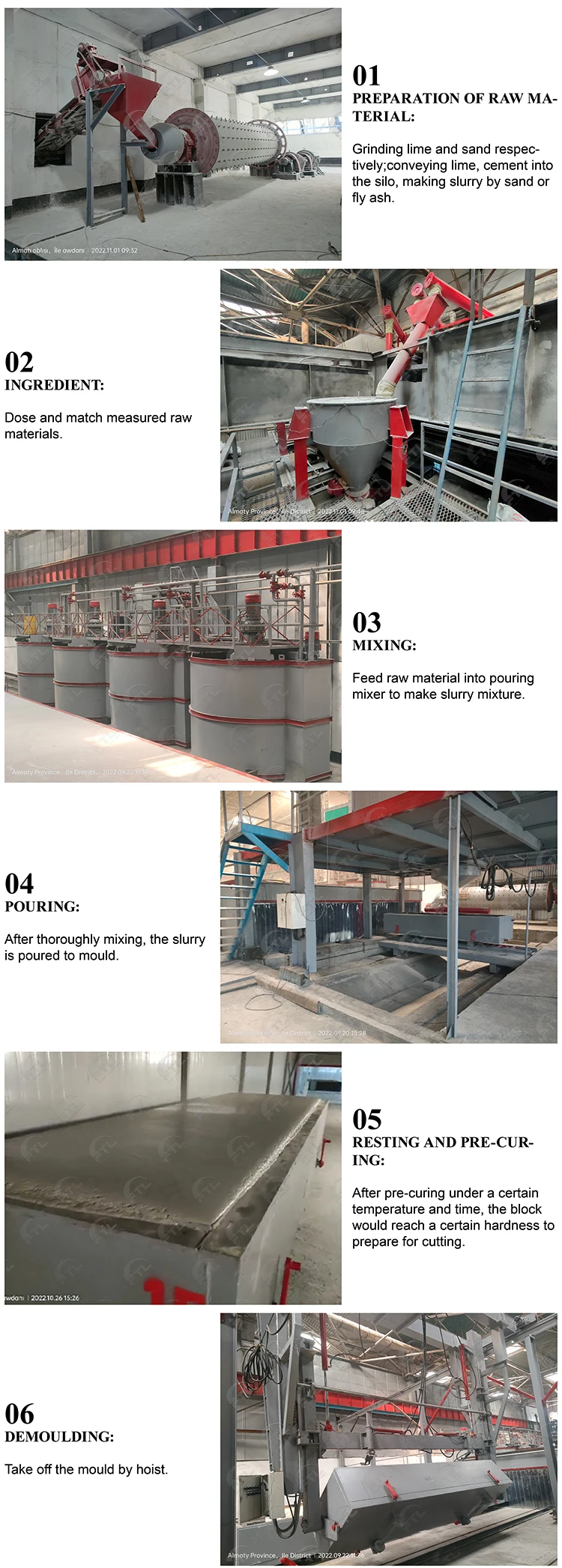

Lngredient Pouring

The batching, mixing, pouring are all controlled by one central control system, the main equipments consists of electronic measuring system, the feeding, conveying, pneumatic control and the valve, casting and mixing machine. The whole technics process all carried out by the central control system, no need the labor to control, which ensure the precise of the batching, then guarantee the product quality.

The batching, mixing, pouring are all controlled by one central control system, the main equipments consists of electronic measuring system, the feeding, conveying, pneumatic control and the valve, casting and mixing machine. The whole technics process all carried out by the central control system, no need the labor to control, which ensure the precise of the batching, then guarantee the product quality. We usually adopt the fixed casting, the casting machine use the wear resist propeller spiral type, which beat up in a higher speed to ensure all the raw material are mixed equally.

The lime and the cement are separately fed into the lime and cement measuring tank through the spiral conveyor, and measured by the electronic measurer, then discharge into the casting mixer according to the instruction.

The fly ash slurry go through the slurry pump to the batching house, then measured through the electronic measuring tank, after slurry reach the requirements of the batching, it will be discharged into the casting machine according to the instruction.

The Al powder measured by the manually, poured into the al powder mixer to make the suspension, we match the slurry every mould, then the suspension will be directly injected into the casting mixer.

Before casting, the slurry temperature should meet the requirements of the technics. If didnt reach will use the steam. While casting, the mould transfer through the ferry car to the pouring mixer.

After casting, the mould transferred through the ferry car to the resting room and pre-curing. During this process, the blending Al powder will have reaction, the hydrogen discharge, at the same time, under the action of Si and Ca material, the slurry will become the solid body, the hydrogen was held, then form the fine air hole, the body expanded.