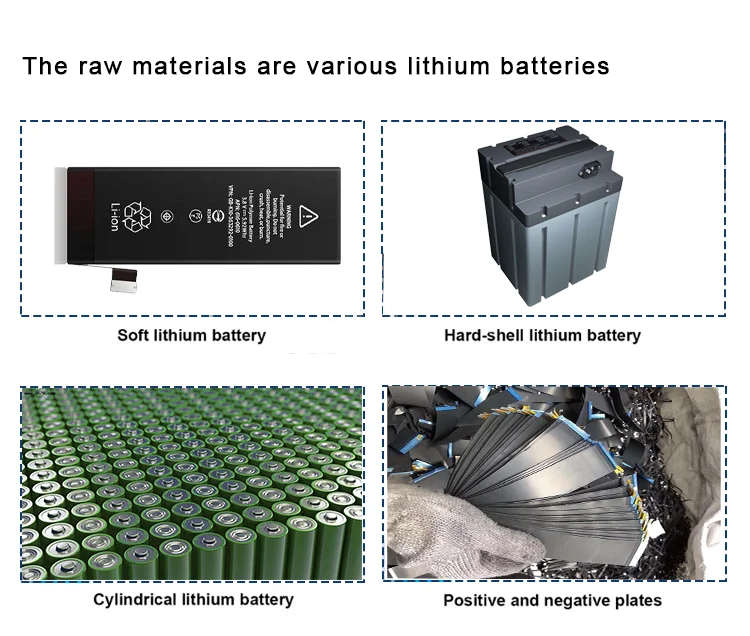

Waste Lithium Battery Recycle Production Line

In order to adapt to market needs and based on current environmental protection factors, Henan Fantianliang Machinery & Equipment Co., Ltd., a large-scale manufacturer specializing in the production, research, and development of environmental protection recycling equipment, has continued its efforts in this area.

Henan Fantianliang Machinery & Equipment Co., Ltd. is a large-scale manufacturer specializing in the production, research and development of environmental protection recycling equipment. In order to adapt to market needs, based on current environmental protection factors, we have continued to innovate in the industry, and developed, designed and manufactured : environmentally friendly lithium battery crushing and sorting equipment, lithium battery positive and negative plate crushing and sorting equipment, circuit board crushing and recycling equipment, wire and cable crushing and recycling equipment, and so on.

Lithium battery recycling and processing equipment mainly uses physical recycling methods, which has the characteristics of green, low carbon, energy saving and environmental protection, and takes into account both economic and environmental benefits. The entire recycling process has achieved industrial automation, with high recycling efficiency. The recycling rate of valuable components of used lithium batteries has reached more than 90%. Cobalt, lithium, copper and plastic in waste lithium batteries are all valuable resources and have high recycling value.

Main equipment of Lithium Battery Processing Production Line

Shredder: Shredded lithium batteries into smaller pieces.

Crusher: For the secondary crushing of shredded materials.

Grinder: For the grinding of the crushed materials.

Separation Machine: Separate the materials after being ground.

Collector: Collect and release the dust .

Pulse Purifier (Air Cleaner): Clean all the dust produced during the operation of the whole system.

Classifying Screen: Screen the materials sorted by the separation machine, and screen out of large metal materials.

Magnetic Machine: Separate nickel from the metals.

Gravity Separator: Separate those finer materials got from the screening machine and separate the metal completely.

High-pressure blower: Keep the whole system in a negative state so as to collect the materials and purity the air.